ISO High quality concrete end hook steel fiber

Polycarboxylate Superplasticizer Liquid Water Reducer Superplasticizer For Concrete

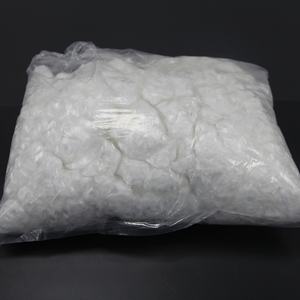

Construction Cement Polypropylene Reinforcing fiber Concrete additive Polypropylene fiber Synthetic PP fiber

MPEG 2400 Raw Material of Polycarboxylate Based Superplasticizer Concrete Admixtutre Polyethylene Elycol Monomethyl Ether

chemical auxiliary agent Defoamer/Anti-foaming Agent/Defoaming Agent for drilling fluid additive

Hot s PS Wall Panel Polystyrene Ceiling Moulding 3D Wall Concrete Panels Waterproof shower wall Cladding Panel

Polycarboxylate Superplasticizer is a high performance water reducing agent, which is a cement dispersant used in cement concrete applications.There are two types of chemically, the main chain is methacrylic acid, the side chain is a carboxylic acid group and MPEG (Methoxy polyethylene glycol), a polyester structure. The other one is polyacrylic acid as the main chain, and the side chain is Vinyl alcohol polyethylene glycol.

Polycarboxylate superplasticizer has a strong dispersion effect on cement, which can greatly improve the fluidity of cement mixture and concrete slump.At the same time, the water consumption is greatly reduced, and the workability of the concrete is significantly improved, and the slump loss of the concrete is small.It can greatly reduce the amount of water and significantly increase the strength of concrete at various ages.

What should you watch out for when using polycarboxylate Superplasticizer water reducer?

1.When the polycarboxylic acid admixture is tested (in production), only the basic amount is reached, the initial workability of the concrete is satisfied, but the concrete loss over time is greater.Therefore, in the trial (production), the dosage should be increased appropriately (ie, the saturation amount is reached) to solve the problem of large slump loss.

2.When the amount of cementing material is reduced, the water-to-binder ratio should be more strictly guaranteed during the production process.If there is a large loss of slump, it can only be achieved by increasing the amount of admixture and adding the admixture twice.Do not solve by adding water, otherwise it will cause a significant drop in strength.

3.Polycarboxylate water reducer is a high water reduction rate, high dispersion product,In production control, the workability of concrete should be measured by the fluidity index (expansion) of concrete. The slump can only be used as a reference value.

4.The strength of concrete is mainly determined by the water-to-binder ratio. The polycarboxylate superplasticizer has the characteristics of high water reduction rate, and it is easy to reduce the water consumption in the production mix ratio, so as to reduce the water-to-binder ratio and reduce the overall cost of concrete. In the production, the fluctuation of raw materials is larger than that of the test. In order to better exert the performance of the poly-sanoic water-reducing agent product, the influence of the raw material condition and the environmental temperature on the workability of the concrete should be taken at any time,adjusting the admixture dosage in time.

5.Polycarboxylate water reducing agent can not be mixed with naphthalene water reducing agent.Rinse the mixer and mixer that have been used with naphthalene-based water reducing agent when using it, otherwise it may cause loss of water reduction.

6.The polycarboxylate water reducing agent should avoid contact with the iron material.Since polycarboxylate water reducer products are often acidic, long-term contact with iron products will slowly react, and even the color will become darker and darker, resulting in a decrease in product performance.It is recommended to store in polyethylene plastic bucket or stainless steel bucket to ensure its performance stability.

Cie-China.org is the leading foam concrete additives provider providing concrete foaming agent, superplasticizer,foam concrete strength enhancer for lightweight concrete, CLC blocks. If you are looking for superplasticizer, please feel free to contact us.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.