ISO High quality concrete end hook steel fiber

Polycarboxylate Superplasticizer Liquid Water Reducer Superplasticizer For Concrete

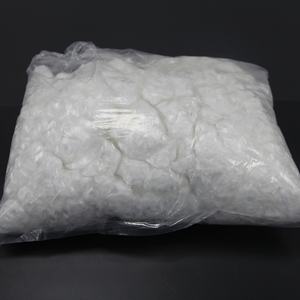

Construction Cement Polypropylene Reinforcing fiber Concrete additive Polypropylene fiber Synthetic PP fiber

MPEG 2400 Raw Material of Polycarboxylate Based Superplasticizer Concrete Admixtutre Polyethylene Elycol Monomethyl Ether

chemical auxiliary agent Defoamer/Anti-foaming Agent/Defoaming Agent for drilling fluid additive

Hot s PS Wall Panel Polystyrene Ceiling Moulding 3D Wall Concrete Panels Waterproof shower wall Cladding Panel

Causes of cracking of foamed concrete foamed cement produced by foam concrete machines:

1. Uneven materials used.

Such as ordinary cement products, if you don't use sand also exists the problem of craze, if use the sand but don't use the stone, so his strong degree is not enough, after a few years or crack will happen, in the same way, if the trial stones, not using reinforced, after decades of words will also appear crack, so cracking phenomenon is not accidental, so we can learn that the cement type of products is not long withstand the impact of the bad weather, in the actual production, cement foamed cement foaming machine production, why will often in concrete cracks, and use of materials is not uniform.

2. Influence of water-cement ratio and curing conditions.

The evaporation of moisture has a direct influence on the cracking of foamed concrete.The water-cement ratio of foamed concrete is often as high as 0.7 or even 0.8, and the excess water will evaporate out when exposed to high temperature or dry environment, thus making the foamed concrete shrink and crack.Especially in the early forming, when the lack of effective maintenance, this situation is particularly serious.It can be seen that low water-cement ratio is a key factor to ensure the foamed concrete does not crack.

3. Influence of cement content and type.

Ordinary Portland cement in the hydration hardening process of solid phase volume is increased, and cement water system is shrinking.Secondly, the hydration process of cement is also accompanied by exothermic heat, causing initial volume expansion and contraction when cooling, leading to an increase in apparent shrinkage.In addition, the cement hydration process also exists in the phenomenon of self - shrinkage.Therefore, in general, if other conditions are basically the same, the amount of cement increases, the shrinkage of foamed concrete will increase correspondingly.Not all cement contracts when it is hydrated. For example, the volume of expanded cement does not shrink after hydration, but increases, which can make up for the volume shrinkage of the system to some extent.But expanded cement can also affect other properties of foamed concrete.

4. Influence of aggregate.

Adding aggregate with constant volume can effectively reduce concrete shrinkage, but only fine aggregate can be added in foamed concrete.However, as the aggregate is inert material, too much mixing will lead to the reduction of concrete strength.

To sum up, the reasons for the cracking of foamed concrete cement are as follows: in addition to the non-uniformity of materials and the flexibility of materials mentioned above, the internal stress of the same materials, thermal shock, dry shrinkage, and crystallization of materials are all important reasons for the cracking of foaming cement.

Cie-China.org is the leading foam concrete additives provider providing concrete foaming agent, superplasticizer,foam concrete strength enhancer for lightweight concrete, CLC blocks. If you are looking for foaming agent, please feel free to contact us.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.