ISO High quality concrete end hook steel fiber

Polycarboxylate Superplasticizer Liquid Water Reducer Superplasticizer For Concrete

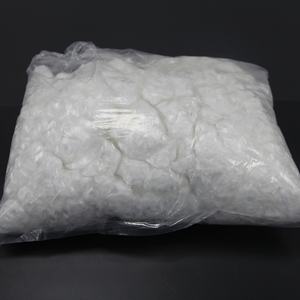

Construction Cement Polypropylene Reinforcing fiber Concrete additive Polypropylene fiber Synthetic PP fiber

MPEG 2400 Raw Material of Polycarboxylate Based Superplasticizer Concrete Admixtutre Polyethylene Elycol Monomethyl Ether

chemical auxiliary agent Defoamer/Anti-foaming Agent/Defoaming Agent for drilling fluid additive

Hot s PS Wall Panel Polystyrene Ceiling Moulding 3D Wall Concrete Panels Waterproof shower wall Cladding Panel

Air, nitrogen, carbon dioxide, or oxygen is introduced into the concrete slurry, and then it is foamed by physical or chemical methods. Finally, it is cured and made into a tangible product with more micro-closed air holes and particular strength. It is called foam concrete.

What is the difference between foam concrete and lightweight concrete?

(1) Different materials

Lightweight aggregate is the use of lighter aggregates instead of ordinary sand and gravel aggregates.

Foam concrete uses conventional aggregates.

(2) Different performance

Because lightweight aggregate is lightweight, lightweight concrete has the characteristics of lightweight, good thermal insulation and fire resistance.

Foam concrete uses physical foaming or chemical foaming methods to introduce a large number of air bubbles into the pavement so that the concrete has lighter bulk density and lower thermal conductivity.

(3) Different bulk density

The weight of lightweight concrete is 800-1400kg/m3. The strength and thermal conductivity of lightweight concrete are higher than foam concrete.

Foam concrete has bubbles, and the bulk density is generally suitable below 600kg/m3.

How to make foam concrete?

Physical foaming refers to mechanical foaming. Air is introduced during full stirring or shearing by machinery, and the sky is wrapped with a surfactant or an aqueous solution of a surface-active substance. In the physical foaming process, to prevent the production of new materials through physical action, the size of the bubble diameter can be controlled by the sheer speed. The bubbles formed by physical foaming are uniform and stable. The type of foaming agent determines the quality of foamed concrete.

At this stage, physical foaming mainly uses the air compressor as an instrument to blow air into the foaming agent, the foaming agent solution is made into foam, and the slurry and foam are mixed to obtain foam concrete. Physical foaming can adjust the performance of foam concrete by controlling the amount of foaming agent. The principle of the compressed air method is mainly to use pressure to blow air into the foam solution to form foam.

What is concrete foaming agent?

Currently commonly used physical foaming agents include: resin soap foaming agent, vegetable protein foaming agent, aluminum sulfonate foaming agent, animal protein foaming agent, hydrolyzed blood gel foaming agent, rosin acid soap foaming Agent. From the perspective of chemical composition, physical blowing agents mainly include surfactants and proteins. The more polar groups in the surfactant structure contain more hydrophilic groups, the stronger the hydrophilic effect and the better the bubble performance. However, the water content on the surface of the foam layer is relatively high, which makes the stability of the foam worse. At the same time, the surfactant can interact with the cement particles, hinder the hydration reaction, and reduce the strength of the foamed concrete. Protein-based foaming agents generate small molecules through the cleavage of peptide bonds and increase hydrophobic groups to form interfaces. Besides, hydrogen bonds are formed between special groups in the unit, so that the solution forms a foam liquid film with higher strength. The vegetable protein foaming agent is soluble in water, hardly affected by water hardness, non-toxic, odorless, strong foaming ability, and dense and creamy foam. However, the stability of the foaming agent product is weak, and the foam stabilization time is short, which cannot achieve large-scale use. Animal protein foaming agent has the characteristics of high foaming ratio, high strength, excellent stability, and low cost.

In summary, the method of using the foaming agent to make foamed concrete is more suitable for foamed concrete over 400 kg/m3. The foam formed by mechanical rotation of the foaming machine or filled with gas, the cells are relatively uniform, the radius is small, and the stability is relatively stable. Most of the cells are closed cells, there are few connected cells, and the water absorption is relatively low.

Cie-China.org is the leading foam concrete additives provider providing concrete foaming agent, superplasticizer,foam concrete strength enhancer for lightweight concrete, CLC blocks. If you are looking for foaming agent, please feel free to contact us.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.