ISO High quality concrete end hook steel fiber

Polycarboxylate Superplasticizer Liquid Water Reducer Superplasticizer For Concrete

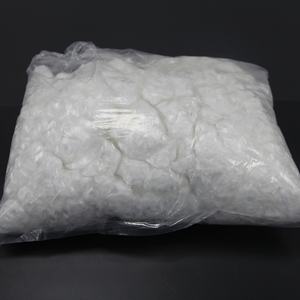

Construction Cement Polypropylene Reinforcing fiber Concrete additive Polypropylene fiber Synthetic PP fiber

MPEG 2400 Raw Material of Polycarboxylate Based Superplasticizer Concrete Admixtutre Polyethylene Elycol Monomethyl Ether

chemical auxiliary agent Defoamer/Anti-foaming Agent/Defoaming Agent for drilling fluid additive

Hot s PS Wall Panel Polystyrene Ceiling Moulding 3D Wall Concrete Panels Waterproof shower wall Cladding Panel

Different types of cement, the plasticizing effect of the water reducing agent is also different.The mineral composition, chemical composition and form of gypsum (as a coagulant) of cement clinker will affect the plasticizing effect of the water reducing agent.In addition, the fineness of the cement, the type and amount of the mixed materials, the freshness, the moisture content, and the temperature may also affect the plasticizing effect of the water reducing agent.

The mineral composition is most affected by the C3A and C2S components.The cement with high C3A content has a poor water-reducing effect, which is because C3A adsorbs the water-reducing agent much higher than other mineral components (a few times larger than C3S).The slag mixture has the least amount of adsorption to the water reducing agent.After the water reducing agent is incorporated into the cement slurry system, the C3A has the fastest hydration speed and the large amount of adsorption. Therefore, a large amount of water reducing agent is adsorbed first.Compared with the low C3A content, the cement with high C3A content has more adsorbent water reducing agent under the same water reducing agent and the same dosage.It will inevitably affect the amount of dispersant required for other minerals (C3S, C2S, C4AF, etc.) in the cement slurry system, thus showing poor fluidity of the concrete.For this reason, if the amount of the water reducing agent is appropriately increased for the cement having a high C3A content, it is possible to greatly improve the fluidity.

When grinding cement clinker, a certain amount of gypsum is generally added to grind together, and here, gypsum is used as a setting agent for cement.Since the temperature in the mill increases during the grinding process, a part of the dihydrate gypsum is removed to convert the partially crystallized water into hemihydrate gypsum, or the entire crystal water is removed to be converted into anhydrite.In addition, in order to save production costs, some cement plants often use anhydrite or industrial by-product gypsum (also anhydrous gypsum) instead of dihydrate gypsum as a cement setting agent.However, if the cement produced is tested according to the relevant cement standards, the general difference is not large. However, when the water reducing agent is added, sometimes it may have a different plasticizing effect.Among them, the most prominent one is that when cement with anhydrous gypsum as a coagulant hits wood calcium and sugar calcium water reducing agent, serious incompatibility will occur.Not only does it not achieve the desired water reduction effect, but it also often causes excessive loss of fluidity or abnormal condensation.

As the gypsum content in the cement increases, the saturation point of the water reducing agent decreases continuously, and the flow rate of the slurry at the saturation point decreases continuously.The mechanism is that gypsum and C3A act to form ettringite to cover the surface of C3A particles, preventing C3A from further hydration, so sulfate can improve the compatibility of water reducing agent and cement.However, high sulfate content has an adverse effect on concrete, and it is not possible to add a large amount of sulfate in order to improve compatibility.

Cie-China.org is the leading foam concrete additives provider providing concrete foaming agent, superplasticizer,foam concrete strength enhancer for lightweight concrete, CLC blocks. If you are looking for superplasticizer, please feel free to contact us.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.