ISO High quality concrete end hook steel fiber

Polycarboxylate Superplasticizer Liquid Water Reducer Superplasticizer For Concrete

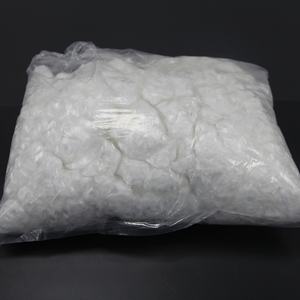

Construction Cement Polypropylene Reinforcing fiber Concrete additive Polypropylene fiber Synthetic PP fiber

MPEG 2400 Raw Material of Polycarboxylate Based Superplasticizer Concrete Admixtutre Polyethylene Elycol Monomethyl Ether

chemical auxiliary agent Defoamer/Anti-foaming Agent/Defoaming Agent for drilling fluid additive

Hot s PS Wall Panel Polystyrene Ceiling Moulding 3D Wall Concrete Panels Waterproof shower wall Cladding Panel

Foam concrete is foamed by the foaming system of the foaming machine, and the foaming agent is fully foamed mechanically, and the foam and the cement slurry are uniformly mixed, and then casted by the pumping system of the foaming machine, and the natural curing station is adopted.

Compared with physical foaming cement, chemical foaming cement does not need to use a foaming agent, and its foaming is rapid, the efficiency is high, the foam is rich, and the foam stability is good. Moreover, by adjusting the amount of foaming agent and the external environment, it is easy to adjust the amount of bubble generation and the size of the bubble, and produce products of different specifications, making it possible to produce low-weight products.

The chemical foaming method uses a chemical reagent to chemically react inside the slurry to form a gas, thereby producing a foamed concrete.

Since internal chemical reactions are difficult to observe and difficult to control, the key to chemical foaming is to control the rate of chemical reaction and the rate of solidification of the slurry to achieve a dynamic equilibrium between gas formation and condensation hardening.

The chemical reagents currently applicable to the preparation of foam concrete are: calcium carbide, aluminum powder, ammonium salt, hydrogen peroxide, and the like.

Calcium hydroxide and acetylene are the result of the reaction of calcium carbide with water. However, the reaction process is too intense, and the gas generation rate is significantly faster than the slurry hardening speed, so that the formation of the bubbles is not stable enough to overflow the slurry in a short time, forming a large number of irregular holes in the surface.

Acetylene is a flammable and explosive gas, so calcium carbide is not suitable for use as a blowing agent.

The main principle of foaming of aluminum powder is that the aluminum powder reacts with water in the slurry under alkaline environment to release hydrogen.

The pores are formed by the expansion of hydrogen in the slurry. However, the amount of gas generated is small, and it is mostly used for high-density foamed concrete.

The ammonium salt decomposes in the alkaline environment of the concrete to produce ammonia gas, and the reaction rate is still insufficient even if the temperature is raised.Therefore, the ammonium salt blowing agent cannot meet the demand for chemical foaming.

Hydrogen peroxide can be redoxed with other chemical reagents to obtain O2, and the reaction rate and the solidification rate of the slurry can be roughly balanced, and the foaming effect is good.

Hydrogen peroxide has a good effect as a chemical foaming agent, and the gas generation rate is controlled by controlling the water temperature, the hydrogen peroxide concentration, and the amount of the catalyst.

Hydrogen peroxide is easily dispersed in the slurry, and the generated 02 has a larger specific gravity than the gas generated by other blowing agents, and can be uniformly and sequentially foamed from the bottom to the top. Therefore, hydrogen peroxide is a suitable blowing agent.

Cie-China.org is the leading foam concrete additives provider providing concrete foaming agent, superplasticizer,foam concrete strength enhancer for lightweight concrete, CLC blocks. If you are looking for foaming agent, please feel free to contact us.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.