Maydos UV Resist Wall Outdoor Coating Waterproof Exterior Paint Concrete Walls Roller Paint Outdoor Wall Paint for House

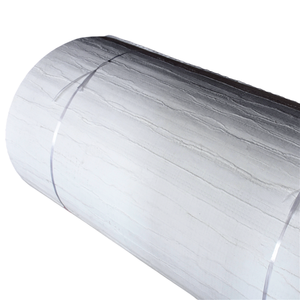

thermal insulation popular graphene aerogel for

Silica Aerogel thermal insulation blanket low thermal conductivity

99 Min Water Resistance Aerogel Powder Insulation for metal building and steam pipe

Promotional Products Whole High Quality Polyethylene Synthetic Fibers For Concrete

Customized foam hand liquid soap foam body soap foaming agent for liquid soap

Polypropylene fiber (PP fiber) is a high-strength bundle fiber made of polypropylene as the primary raw material and manufactured by a unique production process. Adding foam concrete or mortar can effectively control the micro-cracks caused by the solid-plastic shrinkage, dry shrinkage, and temperature changes of the pavement, and prevent and suppress the formation and development of cracks. PP fiber can also improve the crack resistance and impermeability of concrete, impact resistance, and earthquake resistance.

Therefore, polypropylene fiber PP fiber for concrete can be used in the covering of bridge decks and pavements (roads and airport runways), various applications in mining and tunnel engineering, railways, high-rise buildings, slope fixing, fire protection facilities, concrete repairs, industrial waterproofing of roofs, walls, basements, pools and roof gardens of civil construction projects, various precast specific CLC products, etc.

Performance parameters of polypropylene fiber PP fiber

Test item | Test result |

Fiber density,g/cm3,g/cm3 | 0.91 |

Equivalent diamete,um | 34.20 |

Breaking strength,Mpa | 599 |

Elongation at break,% | 27.6 |

Modulus (1% tangent),Mpa | 4665 |

Melting point,℃ | 169 |

Effect of polypropylene fiber PP fiber in concrete

1. Prevent shrinkage cracks of foam concrete;

2. Improve the impact strength and peel resistance of the wall surface;

3. Improve the abrasion resistance of the wall;

4. Improve the impermeability of the wall surface;

5. Improve freeze-thaw resistance;

6. Enhance the tendon function;

7. Prevent the mortar from cracking and prevent crack growth;

8. Replace (for plastering) wire mesh.

Properties of polypropylene fiber PP fiber

1. It is easy to disperse in mortar or concrete, and it is not easy to agglomerate, which effectively guarantees its anti-cracking performance;

2. Easy to use, no need to change the mortar ratio, put the fiber into the mortar mixture and add water and stir well;

3. As the fiber fineness is large and evenly distributed in the mortar, the bonding strength between the plastered surface and the substrate is improved;

4. The fiber has stable chemical properties, strong acid, and alkali resistance, and can be used in any project.

Polypropylene fiber PP fiber uses

1. According to the amount of concrete to be mixed each time, according to the requirements of the mixing ratio (or the recommended amount), the weight of the fiber added each time is correctly calculated. After the gravel is prepared, polypropylene fiber is added. It is recommended to use a forced mixer.

2. Add the aggregate together with the fiber into the blender, but it must be ensured that the fiber is added between the aggregates, dry mixing for about 30 seconds, adding cement and water, and wet mixture for about 30 seconds to disperse the fibers fully.

3. Random sampling after the blending is completed. If the fiber has been uniformly dispersed into monofilaments, the concrete can be put into use. If there are still bundled fibers, extend the mixing time by 20-30 seconds and then use.

4. The concrete added with road fiber is ultimately the same as the ordinary concrete construction and maintenance process.

Recommended dosage of polypropylene fiber PP fiber

The recommended amount of mortar per cubic mortar is: 0.9-1.2kg

The recommended amount of concrete per cubic concrete is: 0.9-1.8kg

Specifications and packaging of polypropylene fiber PP fiber

Basic specifications: 3 ~ 60mm

Basic packaging: 0.9kg/bag or 1.0kg/bag with film packaging; outer packaging with woven bag.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.